Prevents product damage during storage and transit.

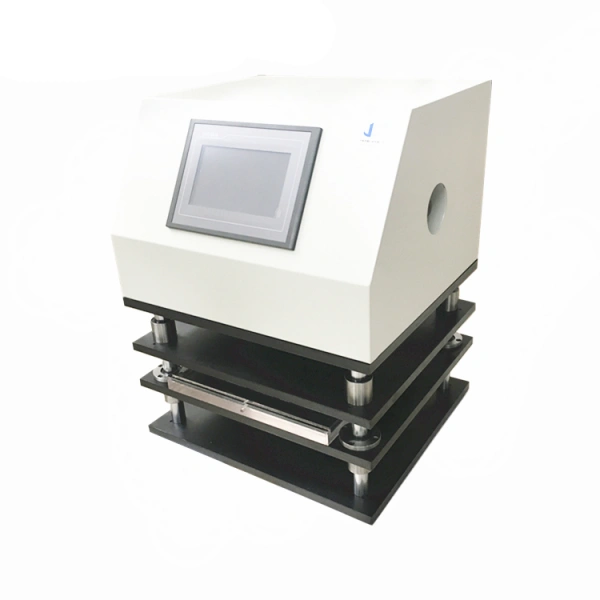

Package Compression Tester

Ensures packages withstand stacking loads.

About Us

Packge Compression Tester

The Package Compression Tester is designed to evaluate the compressive strength, deformation characteristics, and stacking performance of corrugated cartons, paperboard boxes, composite packaging, and finished transport packages under static load conditions. It is widely used in packaging design verification, quality control, transportation simulation, and R&D testing. This instrument is an essential tool for ensuring packaging reliability and compliance with international standards.

Main Applications

- Measure the compressive resistance of shipping containers and packages.

- Simulate stacking conditions to assess long-term deformation and stability.

- Verify packaging design, material selection, and manufacturing process improvements.

- Support product acceptance testing, third-party certification, and compliance verification with standards such as ASTM and ISO.

Key Features

- HMI touch screen parameter setting and test operation

- Industrial-grade PLC control system

- Two test modes of maximum bursting force and constant pressure resistance

- Automatic constant pressure compensation adjustment function

- with automatic data statistics

- Liquid collection device to avoid contamination in case of sample rupture

- Non-standard test sizes can be customized

- An RS232 port and professional computer software are available.(optional)

Main Parameters

| Test Range | 2000N(or as required) |

| Accuracy | 1% FS |

| Time range | 0-10000S |

| Platen size | 250mm*300mm(or as required) |

| Power | AC 110~220V |

Package Compression Testing Standards Compliance

- ASTM D642 — Standard Test Method for Determining Compressive Resistance of Shipping Containers, Components, and Unit Loads.

- ISO 12048 — Packaging — Complete, filled transport packages — Compression and stacking tests using a compression tester.

- Other customer-specific or industry-specific standards available on request.

Package Compression Testing Industries Served

- E-commerce and logistics — shipping box quality control and transit simulation

- Food & beverage — outer packaging integrity testing

- Medical devices & pharmaceuticals — product protection verification

- Home appliances & electronics — large carton compression testing

- Paper & corrugated board manufacturers — product quality evaluation

- Third-party testing labs & research institutes

Package Compression Testing Procedure

- Sample Preparation – Assemble and seal the sample according to the relevant standard or actual shipping conditions.

- Positioning – Place the sample centrally between the compression plates.

- Parameter Setting – Input target load, loading speed, and hold time.

- Testing – Start the test, record force–displacement data, and save peak load and deformation values.

- Reporting – Generate test reports with curves, statistics, and compliance evaluation.

The tester measures package strength and stacking performance for quality compliance.

The importance of package compression testing

The Package Compression Tester evaluates package strength, deformation, and stacking to ensure quality and standard compliance.

1. Product Protection

The primary function of packaging is to protect the product inside. Compression testing verifies that the packaging can resist the vertical loads it will face during stacking in warehouses, containers, and delivery vehicles. If the packaging collapses under load, products may be crushed or deformed, leading to financial loss and customer dissatisfaction.

2. Compliance with Standards and Regulations

Many industries require packaging to meet specific international standards such as ASTM D642 or ISO 12048. Compression testing ensures that packages comply with these requirements, which is essential for certification, quality audits, and contractual obligations. Meeting these standards also helps companies avoid penalties, product recalls, or shipment rejections.

3. Cost Optimization and Material Efficiency

Compression testing helps manufacturers find the optimal balance between strength and cost. By accurately assessing packaging performance, companies can reduce material usage without compromising safety. This not only lowers production costs but also supports sustainability initiatives by minimizing waste and improving resource efficiency.

4. Risk Reduction in Logistics and Supply Chain

During transportation and storage, packages are often subjected to stacking, vibration, and handling impacts. Compression testing simulates these real-world conditions, allowing manufacturers to identify weaknesses in design or material before mass production. This proactive approach reduces the risk of product damage, returns, and disputes with customers or logistics partners.

Cell Instruments Advantages

1.Professional manufacturer background

With many years of R&D and production experience, we focus on packaging, medicine, food, and electronics. We have a strong R&D team and modern manufacturing system to ensure leading product quality and technical level.

2.Strong custom development capabilities

With deep technical accumulation, we provide tailor-made solutions, including function adjustment, software customization, and automation transformation, to flexibly respond to various testing needs and improve testing efficiency.

3.Complete after-sales service system

With a technical support and after-sales service network covering the national and overseas markets, we provide full-service services such as operation training and remote diagnosis to ensure that customers are worry-free and minimize downtime.

Supports sustainable packaging design.

Why Choose Our Package Compression Tester?

01

Proven Industry Expertise

With years of experience in packaging testing, we understand the specific needs of different industries — from e-commerce cartons to heavy-duty wooden crates. Our deep knowledge of ASTM, ISO, and customer-specific standards ensures that every test meets both performance and compliance requirements.

02

Comprehensive Technical Support

We offer more than just equipment. Our services include sample testing, operator training, calibration guidance, and lifetime technical assistance. This ensures that your testing process remains accurate, efficient, and trouble-free throughout the product’s lifespan.

03

Advanced Software for Precision and Efficiency

Equipped with robust control and analysis software, our system allows batch testing, lot management, and comprehensive statistical reporting. Users can easily export force–displacement curves, peak values, and compliance reports in formats such as PDF, Excel, or CSV.

04

Custom Solutions to Meet Special Requirements

From oversized test spaces for bulk packaging to high-capacity models for heavy loads, we can design and manufacture tailor-made systems. Optional features such as environmental chambers allow testing under controlled temperature and humidity, simulating real-world storage and transportation conditions.

Frequently Asked Questions

Can the results be used for certification or bidding purposes?

Yes. Our reports can be generated according to ASTM, ISO, or customer-specific standards for certification and tender requirements.

Can it test irregular-shaped packages?

Yes. Adjustable fixtures and custom supports are available for non-standard shapes and dimensions.

Does the sample need special preparation?

Generally, samples should be prepared and sealed according to the test standard or actual shipping condition.

How do I choose the right maximum test force?

The selection depends on expected load capacity and safety factors. Standard cartons often require 5–10 kN, while heavy-duty crates may need 50 kN or more. We can provide selection guidance.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985